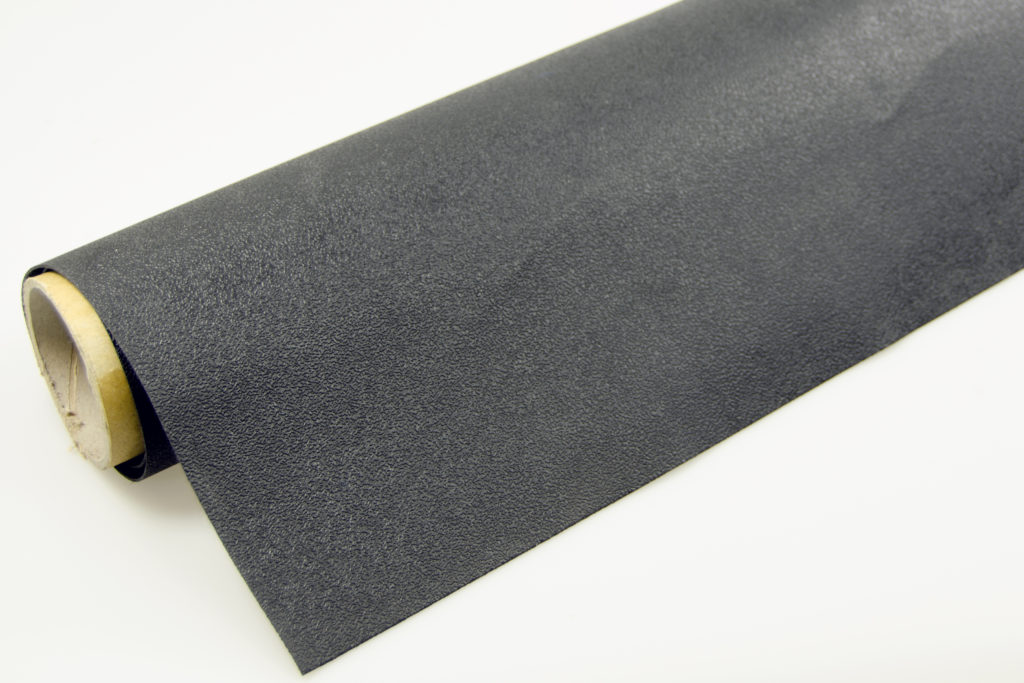

Thermoplastic Olefin (TPO) Fabrics

Our Thermoplastic Olefin (TPO) fabrics feature an extruded non-woven TPO film surface that characterized by excellent water and weathering repellency, long-term durability, UV and abrasion/shock resistance and excellent anti-slip properties. Moreover, TPO continues to be workable in extremely low temperatures ( -70ºC – 200ºC), and also withstands degradation when exposed to certain oils, greases and chemicals.

TPO film can be tailored to specific applications by adjusting the surface textures/appearance and also by laminating it to PE, PVC, ABS, or other textiles.

These traits make TPO Fabrics suitable for surfaces that will see high traffic or extreme exposure and wear.

TPO vs PVC

TPO is also regarded as the “greener” product when compared against similar materials such as PVC. Unlike PVC, TPO is not derived from chlorine-based chemistry thereby avoiding many inherent environmental and health hazards. Rather, TPO emanates from an olefin-based film which is simpler, lighter and environmentally superior to PVC. Furthermore, TPO does not require the addition of plasticizers to remain flexible.

TPO Applications

Consumer applications for TPO fabrics include non-slip matting and padding covers, and as reinforcement for high-wear areas on medical or sporting/recreational equipment.

Industrial applications for TPO include ground sheets, roofing membranes, agriculture coverings, or truck tarpaulins.

Sold with the following specifications:

Widths Available: 54″

Thicknesses Available: 0.1mm – 2.0mm

Packing: 50 yards – 200 yards per roll.

Melt Point: approximately 150ºC – 250ºC

Printable: via Heat transfer